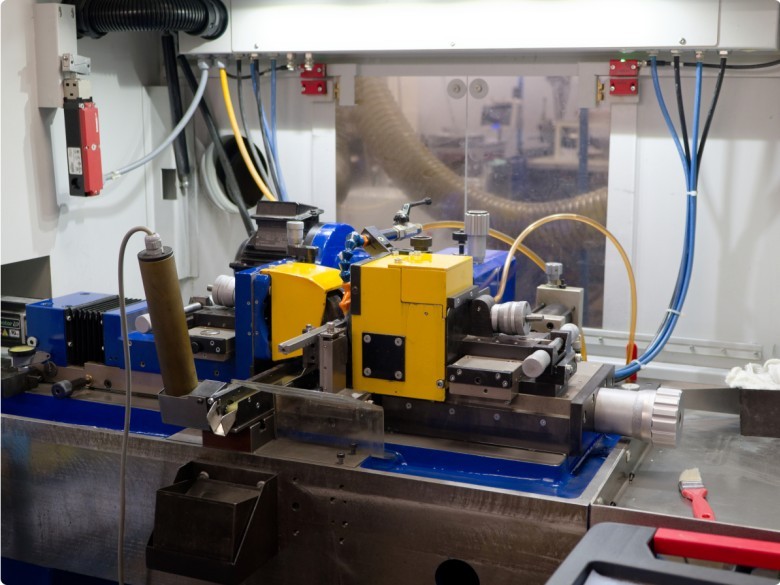

We rectify your material bars

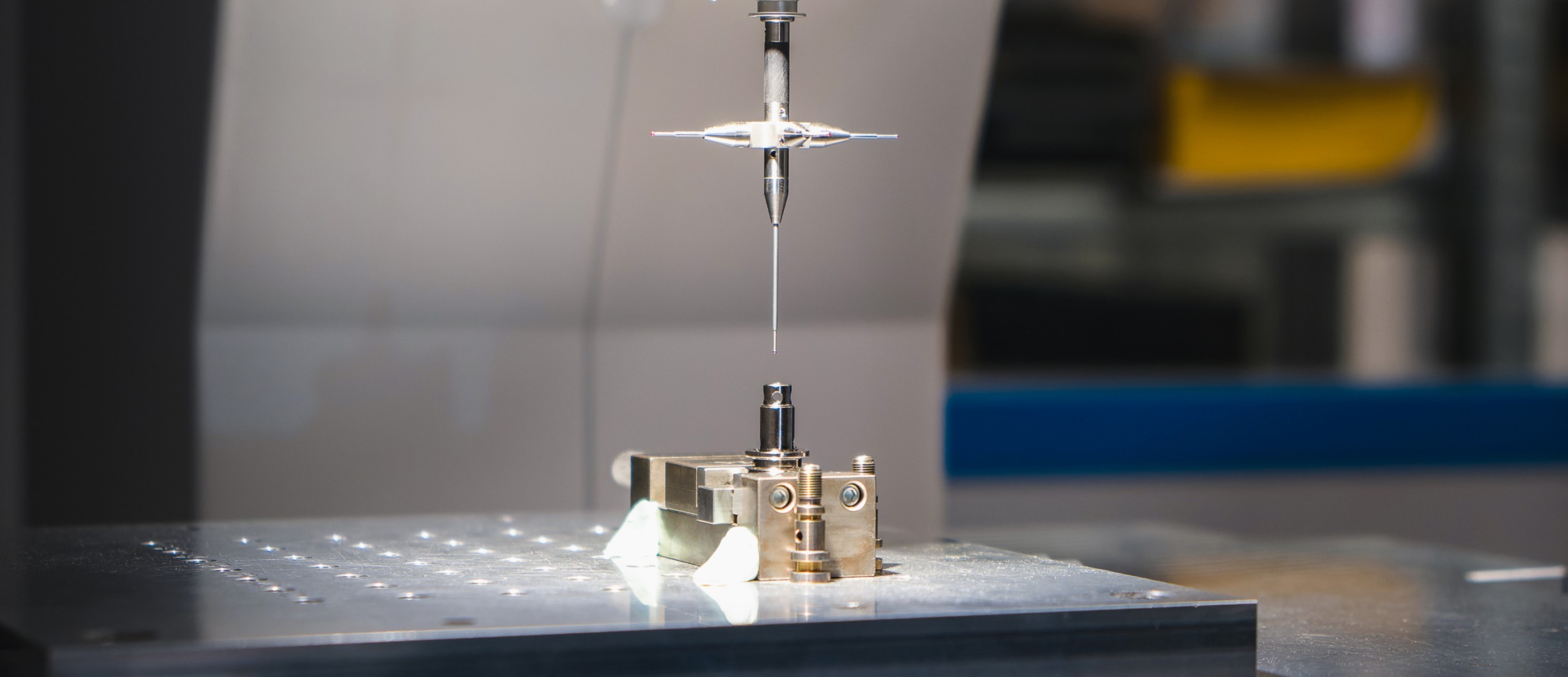

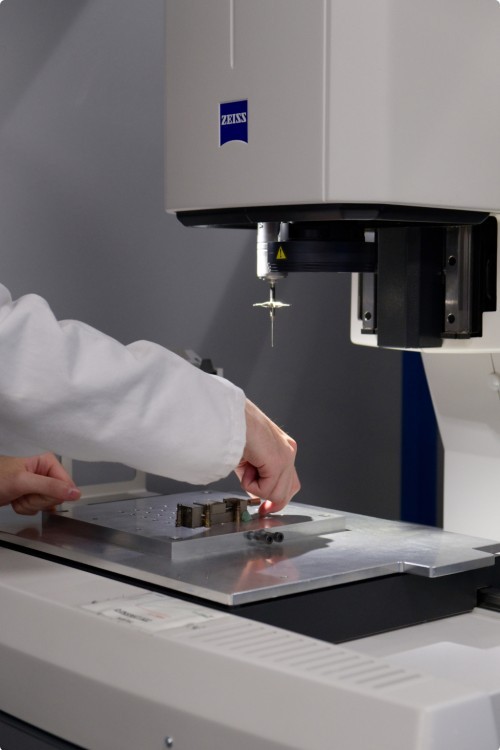

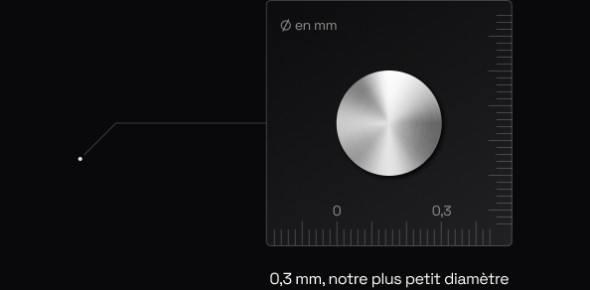

Do you have bars of material that need to be ground for future machining? Contact us. We can grind bars of any material, up to 3 metres long, with a diameter of between 0.3 and 12 mm. One of our specialities in this field is the grinding of potentiometer axes and other axes.